Risk management is a cornerstone of quality management, especially in industries like automotive, pharmaceuticals, and electronics. Failure Mode and Effects Analysis (FMEA) is a proactive approach to identifying potential failures and their consequences. With FMEA software, organizations can streamline the risk analysis process and implement effective corrective actions.

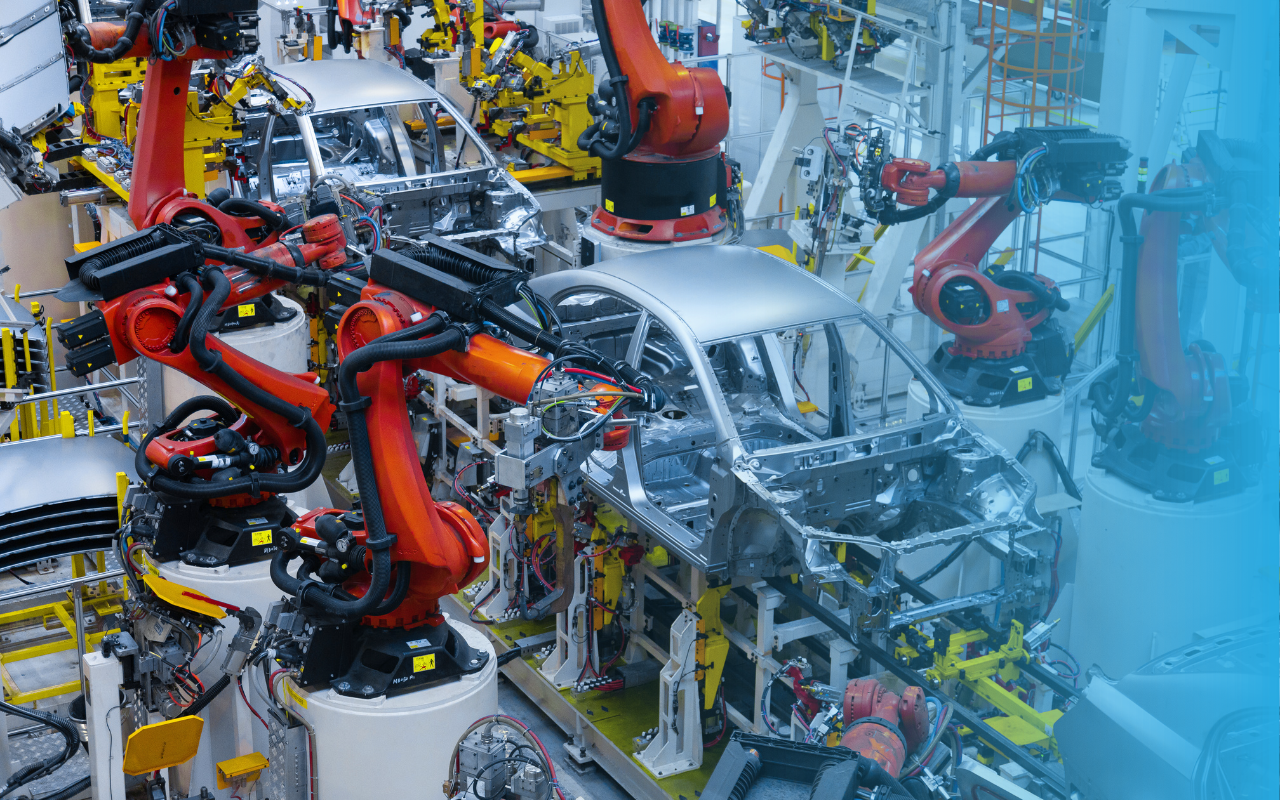

The Role of FMEA in Manufacturing

FMEA is used to evaluate every component, assembly, and process step for potential risks. For example, an automotive manufacturer might analyze a braking system to identify risks such as material fatigue or design flaws.

How FMEA Software Enhances Risk Management

- Streamlined Collaboration: Teams can collaborate in real-time, ensuring all stakeholders are aligned.

- Automation of Risk Scoring: FMEA software automates the calculation of Risk Priority Numbers (RPNs), helping prioritize issues.

- Traceability: Maintain a comprehensive audit trail for all changes and updates.

- Integration with CAPA: Ensure that identified risks lead to actionable preventive measures.

Benefits of FMEA Software

- Enhanced reliability of processes and products.

- Faster response to potential issues.

- Improved compliance with industry standards such as IATF 16949.

Investing in FMEA software enables manufacturers to proactively address risks, improve product reliability, and meet stringent quality standards.